Journal: 5th March 2024

We can retrofit anything.

BakerBrown have long been advocates for reusing and adapting the existing built environment to meet new ideas of occupation, low energy performance, and climate resilience. Most of all we are passionate about reducing the vast amount of raw materials the construction sector consumes annually. As much as 50% of all raw material, that’s 50 billion tonnes, is consumed annually by the construction sector. Working with existing human-processed materials, or ‘Mining the Anthropocene’ as our founder Duncan Baker-Brown calls it, should be a priority for meeting our collective commitment to Net Zero targets.

Existing buildings are from different eras, have different functions, are built in different environments therefore, they require different strategies and responsive design solutions. The world of retrofitting is a lot more than external wall insulation and solar panels and it is not a simple task.

With fuel bills quadrupling, and over 6 million homes in the UK (27 million across Europe) expected to be sent into fuel poverty, high levels of fabric insulation, double-glazing and low carbon energy sources, are now a crucial priority.

BakerBrown have over 25 years of experience working with buildings from the 15th Century through to current, across many typologies from one-off country houses, social housing, listed buildings, commercial office space and even light industrial buildings from the 1980’s.

We have stated in the past that “we will have a go at retrofitting anything, just to prove that it can be done and in a cost-effective way obviously” and we are currently campaigning (along with many others) for a national retrofit programme to be rolled out across the UK, as it could be a major employer and wealth creator, whilst enabling us to meet net zero carbon targets and fuel poverty. We are part of the campaign for VAT on retrofit to match that on new build projects. For over 5 years Duncan Baker-Brown has been one of the judges for the AJ Retrofit Awards, an award we won in 2013. If you would like to read one of Duncan’s opinion pieces here is a link to a recent article in Dezeen

Further details of some of BakerBrown’s recent retrofit projects are below.

The Nook – 1880’s Grade II Listed Victorian Villa housing 6 studio flats – Innovate UK Retrofit the Future project and LETI Case Study

Brief Particulars:

Contract Cost: £130,000

Construction Duration: 7 months

Gross Floor Area: 196m2

Architect / Lead Consultant

The Nook retrofit demonstrates a few important achievements. Firstly, the cost of the retrofit versus the energy saving costs can be used as a benchmark to evaluate future retrofit works. It actually improved on the design stage energy prediction and met the Government’s energy efficiency target for 2050. It also highlights how retrofit need not change the outward appearance of a listed property.

A key feature of the Nook retrofit was that the front elevation was insulated from the inside as the authorities rejected any proposal to externally clad. The design team recognized that this would be a long-term benefit to the wider construction industry as it will afford a chance to evaluate whether or not internal insulation solutions serve to accelerate the decay of solid wall construction or indeed interstitial damp and mould problems – an area of building science which is generally thinly understood by building professionals.

The authorities also insisted on double hung sash windows for the front elevation which were not as efficient as the Passivhaus standard windows used on the other three elevations and no doubt have effected some of the efficiency savings achieved.

The Nook provides a template for retrofitting solid wall rendered buildings of historic importance to the community. There are many thousands of solid walled buildings throughout the UK which pose a retrofit dilemma to the construction industry and property owners alike. If by 2050 our building stock needs to operate at or around 17kg of CO2/m2/annum instead of more like 90 - 120 kg of CO2/m2/annum which would be typical of such buildings, it calls into question whether these buildings are fit for purpose for our energy challenged future. In the UK we have increasingly severe issues of ‘affordable warmth’ for those on low or even middle incomes. The Nook has demonstrated it is possible to tackle a building of this kind and deliver the kinds of energy efficiency necessary to make it fit for a sustainable future without rebuilding it.

Air tightness testing of the finished project recorded a remarkable 2.5 air changes per hour @ 50pa.

We learned some valuable lessons in the way the works were carried out with the tenants in situ. The design team carried out a post occupancy evaluation with the tenants to capture first hand their experiences of the briefing, design, construction and post construction phases. This proved an invaluable exercise for all concerned and helped clear up misunderstandings which had arisen between the building users and the contractors.

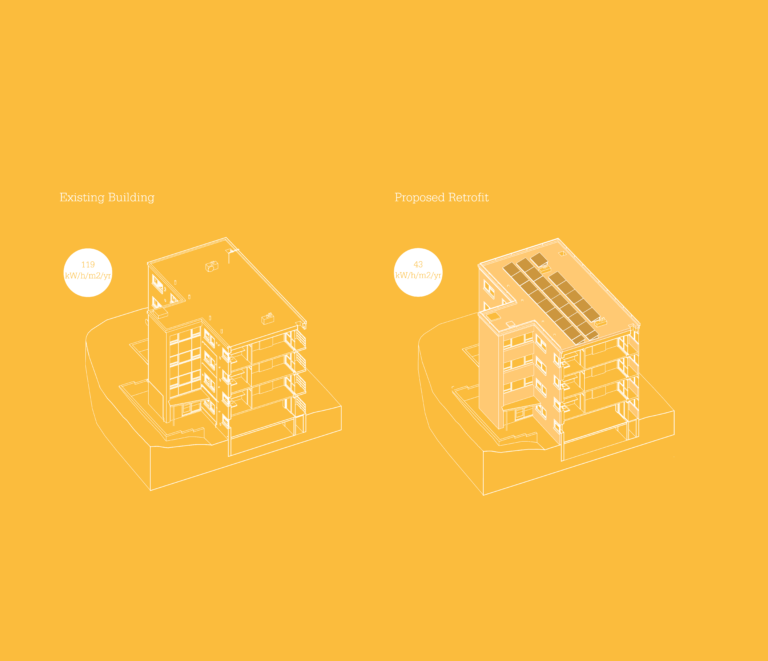

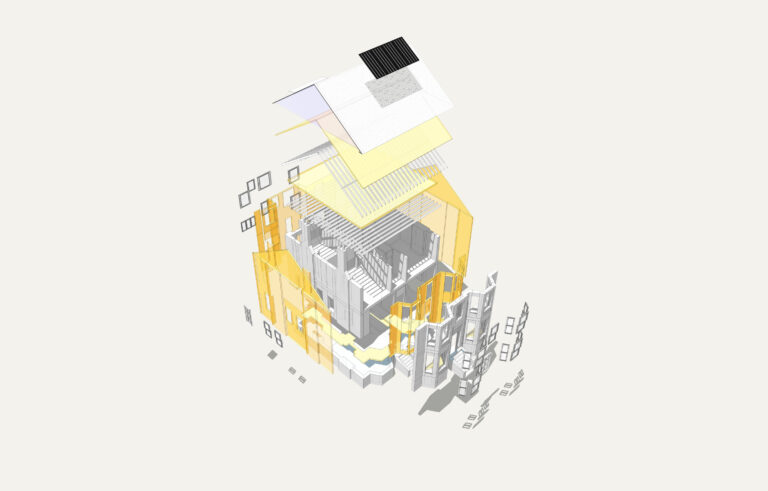

Leach Court – 1970’s social housing tower extension and retrofit

Brief Particulars:

Project: Leach Court, Brighton

Clients: Brighton and Hove City Council

Project Status: Planning

Construction Budget: £25,000,000

Architect / Lead Consultant

BakerBrown have prepared a feasibility study exploring the potential for adding additional sheltered housing accommodation to three existing tower blocks at Leach Court on Eastern Road Brighton. Owned by social housing provider Brighton & Hove City Council, this project also involves the addition of South-facing ‘winter gardens’ to existing properties, additional ground floor community facilities and even 7th floor sheltered bridge structures linking the three separate structures. In short, our brief was to double the number of homes on the site, increase social/ community facilities, and reduce the whole life carbon footprint on site by 50%.

Eco Station – 1910’s (Edwardian) former Fire Station low energy retrofit

Brief Particulars:

Project: Eco-Station, Eco-retrofit of a Former MoD Fire Station into a Eco-Town Visitor’s Centre

Client: East Hampshire District Council

Net Build Cost: £550,000

Construction Duration: 11 months

Gross Floor Area: 661m2

Architect / Lead Consultant

As part of the Bordon Eco-Town, the former MoD’s former garrison fire station, built in 1906 is being converted to become a new visitor’s centre, with offices for the Whitehill Bordon Eco-Town Team and community facilities for the local town. BakerBrown provided an umbrella consultancy for designing and administering of contract on this important eco-retrofit project.

The key driver of the brief was a budget which did not afford super insulated standards throughout the building. Instead BakerBrown and the quantity surveyors devised a strategy of targeted spends to provide those spaces which are most used with the most energy efficiency upgrades. This is a recognition of the affordability issues facing the eco-retrofit agenda of rolling out mass refurbishments across the entire built environment. As such the strategy provides an invaluable route map for building managers in planning similar works.

The building services engineers used IES modelling (Integrated Environmental Solutions), a dynamic modelling simulation tool which provides analysis of how energy is lost in the building and therefore which eco-retrofit measures provide the best solutions for the budget available. We were able to demonstrate a cost benefit analysis for a number of options and strategize phased work for the solutions that could be implemented at a later date.

Community Base – 1970’s commercial office space deep green retrofit

Brief Particulars:

Project: Eco refurbishment

Client: Community Base

Contract Sum: £1.1 Million

Architect/Principal Designer

The Community Base office building in central Brighton underwent a major eco-refurbishment of all its external walls with a view to substantially lowering the carbon footprint, reduce running costs by 26%, and extend the life of the very popular building and iconic Brighton & Hove City landmark.

Our clients had a large building but a modest budget. The building accommodates over thirty charitable organisations and heating costs were a big concern. It is hoped the works will make the spaces not only more economic to occupy but also more comfortable.

At the start of the project, a thermo-dynamic digital model (IES) was commissioned. This highlighted exactly how the building performed before the retrofit works were undertaken, identifying where the major heat loss/ heat gain issues were. A number of different low carbon scenarios were then studied, and pointed out that if the existing façade was overclad, the energy and heating bills would reduce by at least 26%. The model also enabled the client and us, the architects, to plan a phased series of retrofit interventions, starting with over-cladding the façade, that could be implemented as funds became available. This approach ensured the clients gained the biggest low-carbon impact for the least amount of money and resources.

The old 1960’s exterior panels had ‘concrete cancer’ and provided little defence against the salty marine air of Brighton. The inner steel bars had started to rust which in turn cracked the concrete shell. In place of the existing panels is a new skin combining specialised aluminium panels, a thick layer of insulation and new double-glazed windows.

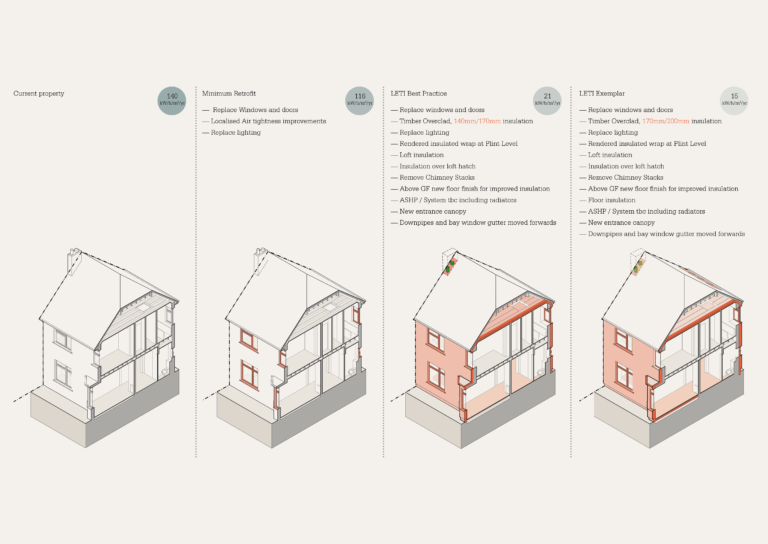

DOHS – Decarbonising the Social Housing Stock Retrofit Routemap

BakerBrown are currently project lead for a study into low energy retrofit best practice for the Greater Brighton Economic Board which is a group of seven local authorities in SE England. This project will last for a year and consider best practice retrofit strategies (for eight different social housing types), starting with how to use current maintenance funds to achieve EPC C and then cost-effective consideration for meeting LETI Best Practice and Exemplar benchmarks. Also included in the study is a comparison of seven different energy standards from SAP and EnergyPlus, to PHPP and IES. We are mapping the carbon footprint of material flows off and onto retrofit sites, the opportunities for specifying local, organic, non-toxic materials, together with the training and employment opportunities large-scale retrofit presents, and of course the issue of fuel poverty.